Hollow structural sections (HSS), also referred to as steel hollow sections or structural steel tube, is a type of manufactured steel that is fabricated into a hollow, tubular section. Common applications for steel hollow sections include columns, welded frames and beams – which may be used across a diverse range of mechanical and construction applications.

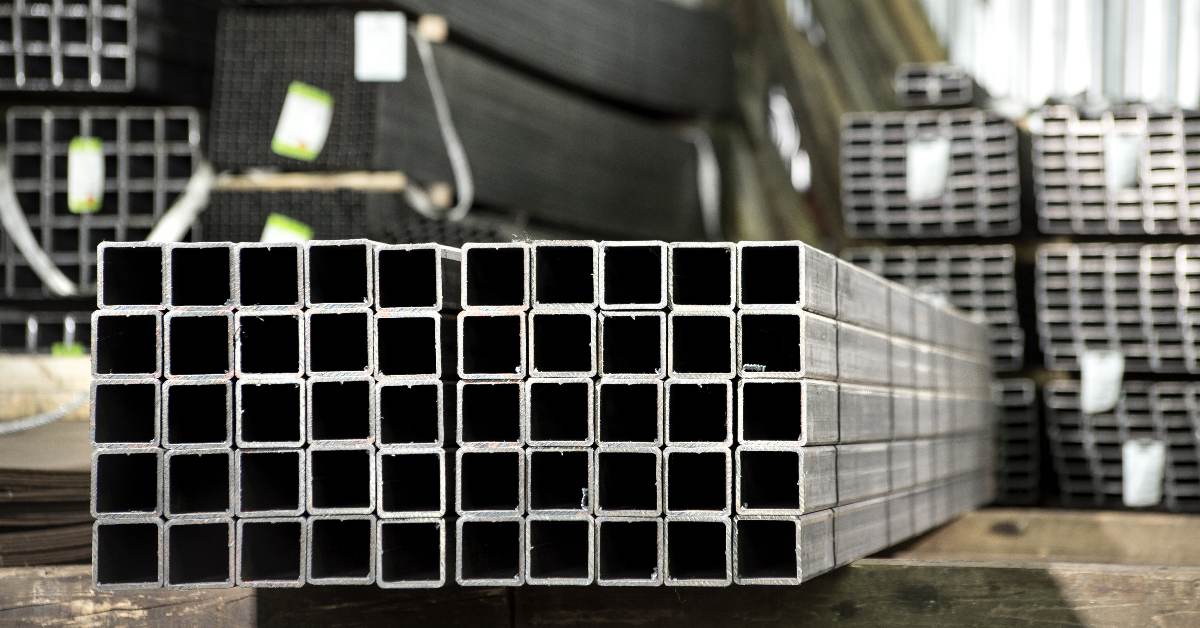

These structural steel tubes are organised into three widely recognised categories; Circular Hollow Sections (CHS), Rectangular Hollow Sections (RHS) and Square Hollow Sections (SHS). Despite their distinct differences, not everyone fully understands the unique functions, and differences, between these three types of hollow structural sections. Read on to learn how these three types of steel sections differentiate.

CHS – Durable & Aesthetically Pleasing

Circular Hollow Section (CHS) steel was the first type of hollow section created. This type of structural steel tube is known for its consistent, aesthetically pleasing lines, clean edges and overall smooth appearance. Hence, CHS steel is commonly favoured for architectural applications that demand a more aesthetically pleasing finish. You’ll find CHS steel commonly used across a broad range of structural, construction and mechanical applications.

SHS – Balance Strength & Symmetrical Appearance

When looking at the functional, aesthetic and structural attributes of steel hollow sections, Square Hollow Section (SHS) steel can be considered the middleman between CHS steel and RHS steel.

The square, flat surface of SHS steel is practical when it comes to joining and welding. Steel fabricators perform minimal edge preparation when working with SHS steel, due to its clean lines. This is where SHS steel poses similarities with Rectangular Hollow Section steel. Due to their similar shapes, SHS and RHS are sometimes referred to as “box sections”.

On the other hand, SHS shares attributes with CHS. Both of these steel hollow section types have a symmetrical appearance; with the SHS taking an equal-sided square shape.

Considering the similarities between the SHS and the remaining types of hollow structural sections, SHS offers steel fabricators and architects a handy balance between aesthetics, functionality and durability.

RHS – Durable & Economical

Rectangular Hollow Section (RHS) steel boasts a flat surface that facilitates an economical structural solution for a diverse range of fabrication works, such as joining. It’s commonly relied upon in construction, structural and mechanical applications.

The rectangular shape of RHS steel is notoriously practical when joining other flat surfaces, as these steel sections only need to be straight cut. Hence, when RHS steel is used, fabricators only need to conduct minimal edge preparation for joining or welding applications. Plus, with the clean lines and impressive structural strength of RHS steel, it is commonly relied upon for architectural aesthetics. Interestingly, RHS is sometimes used to describe SHS steel, even though this is incorrect.

E M Steel Manufacture CHS, RHS & SHS Steel

E M Steel’s trusted team of steel fabricators offer all types of steel cut to length, primed and drilled if required. Among our broad-ranging steel sales, we offer Circular Hollow Sections (CHS), Rectangular Hollow Sections (RHS) And Square Hollow Sections (SHS). For more specifications, be sure to get in touch with our reliable team. With over 120 years of combined experience, we know we’ll find the right steel solution for your job.