Have you noticed some people tend to use the terms “pipe” and “tube” interchangeably? We’ve noticed it’s common for steel pipes and steel tubes to be viewed as one and the same. Sure, they look similar on the surface, embodying a cylindrical, hollow shape, but in reality, they are vastly different products.

Read on to learn what the difference is between steel pipes and steel tubes.

Physical Attributes

Steel pipes and tubes have different diameters, and their diameters are measured differently. Pipes are measured by their inside diameter, while tubes are measured by their outside diameter. Steel pipes can be used for larger applications, while tubes tend to work well with smaller applications.

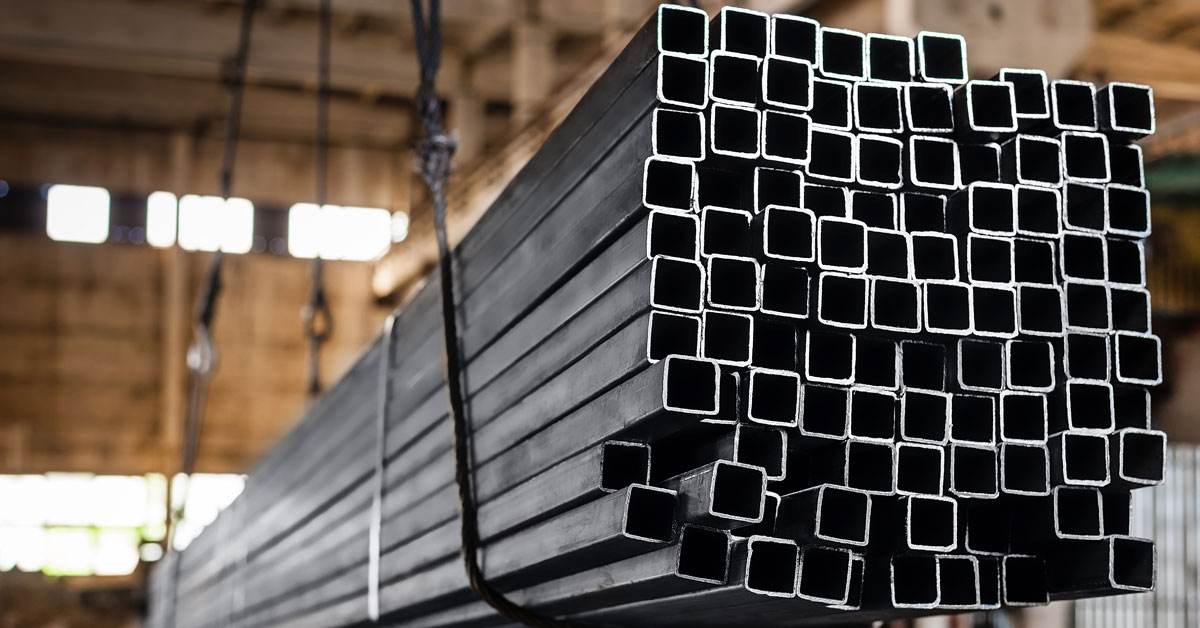

Another way to spot the difference between steel pipes and tubes is their wall shape and thickness. Tubes can be round, square or rectangular. Pipes most commonly have a round shape.

The shape of steel pipes and tubes directly corresponds to their wall thickness. Being able to calculate wall thickness accurately helps to distinguish the strength of the steel tube or pipe. Knowing the strength of the tube or pipe is important, as this directly relates to its usage.

Usage

Steel pipes and tubes vary in their usage and application.

When it comes to pipes, they are used to dispense or transport liquids or gasses. Hence, knowing the tolerance and capacity of the pipe is imperative.

On the other hand, steel tubes are used to support structures. For example, they are used to manufacture pivots in the agricultural industry.

Manufacturing

Because steel pipes and tubes have different applications, they are therefore manufactured differently. Usually, steel tubes require more stringent processes, tests and inspections. Consequently, this delays distribution.

Plus, steel tube production is generally more costly, due to greater labour, energy and material expenses.

In contrast, steel pipe applications can undergo mass production, which can make them far more accessible and less costly than steel tubes.

Materials

When it comes to steel pipes, the materials used to make each pipe differs, which raises their cost. Generally, low alloy steel and carbon steel are primarily used to make pipes. Tubes can be made from steel, brass, copper, chrome, aluminium or stainless steel.

Chemical Elements

The main chemical elements of pipes include carbon, sulphur, silicon, manganese and phosphorus. In contrast, smaller elements are important for the effective manufacturing process of tubes.

While pipes and tubes may appear similar, there are, in fact, countless ways to identify their differences. Having a complete understanding of these differences is imperative in the steel manufacturing industry.

At E M Steel, we’ve been delivering high quality steel, decorative metalwork and fabricated products to South East Queensland’s domestic and commercial building industries for over a decade. With over 120 years of combined experience, you can trust we have the confidence and expertise to get the job done, no matter how challenging. Explore our recent projects, or get in touch with us today.